Outsourcing BIM is smart. But only when it’s done right.

From coordination failures to poor use of building information modeling software, the wrong outsourcing decisions can cost you more than just time. In fact, over 25% of BIM outsourcing projects face rework due to miscommunication or inadequate clash detection.

At Eracoregroup, we’ve seen how avoidable these issues are when teams use the right workflows and tools, like BIM clash detection software, Autodesk Navisworks, and BIM 360 Model Coordination.

In this article, we’ll break down 7 common BIM outsourcing mistakes contractors must avoid, and how to prevent them using proven processes, the right platforms, and expert teams.

Let’s get into it.

Mistake 1: Outsourcing without a clear BIM execution scope

Outsourcing BIM without a clearly defined execution scope is like building without a blueprint, teams are left guessing, and guesswork leads to costly mistakes.

A well-scoped BIM engagement sets expectations from day one: what to model, to what LOD, using which building information modeling software, and by when. Yet, this step is often skipped in the rush to get files moving. In our experience, a significant portion of BIM coordination issues, especially during clash detection in BIM, stem from unclear deliverables and vague responsibilities at the project’s start.

The result?

Delayed deadlines, double work, and disconnected models that require rework during coordination.

To avoid this, every BIM outsourcing engagement should begin with a detailed, agreed-upon scope. It should define:

- Modeling standards, LODs, and file-naming conventions

- QA/QC expectations and software version alignment

- Who is responsible for what (and by when)

- Coordination workflows and review checkpoints

Pro tip:

Don’t overcomplicate it. A simple scope document with clear milestones, software versions, and clash detection software protocols can save weeks of back-and-forth and lay the groundwork for a more effective, collaborative partnership.

Mistake 2: Choosing the cheapest vendor over the right expertise

Cost-saving is one of the biggest drivers behind BIM outsourcing, but chasing the lowest price often leads to the highest pain. Selecting a vendor based purely on cost is one of the most common BIM outsourcing mistakes, especially when complex scopes like clash detection in BIM or prefab detailing are involved. Clash-heavy scopes like feeder routing and panel alignment require field-aware electrical coordination services not just basic modeling.

Why it fails: Low-cost providers may lack experience with advanced building information modeling software, or worse, skip essential coordination steps to cut corners. We’ve reviewed models where basic coordination was done, but proper checks in BIM clash detection software like Autodesk Navisworks or Revitzo were entirely missing. That leads to costly RFIs and change orders downstream.

What to do:

- Proven field experience with your type of project (data center, healthcare, etc.)

- Proficiency in tools like Revit, Navisworks, Revitzo, and 3D clash detection tools

- A process-driven team that provides issue tracking, coordination logs, and LOD documentation

- Familiarity with your standards and local codes

Mistake 3: Ignoring clash detection capabilities

Outsourcing BIM without prioritizing clash detection is like building blindfolded. Clash detection in BIM is a necessity. Yet many contractors mistakenly assume their outsourced team will “take care of it,” only to discover major issues during construction.

A common red flag?

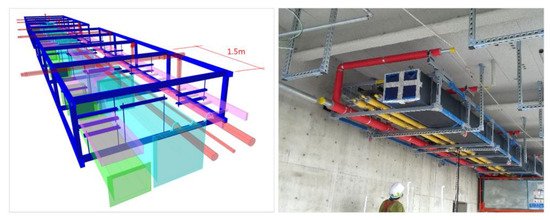

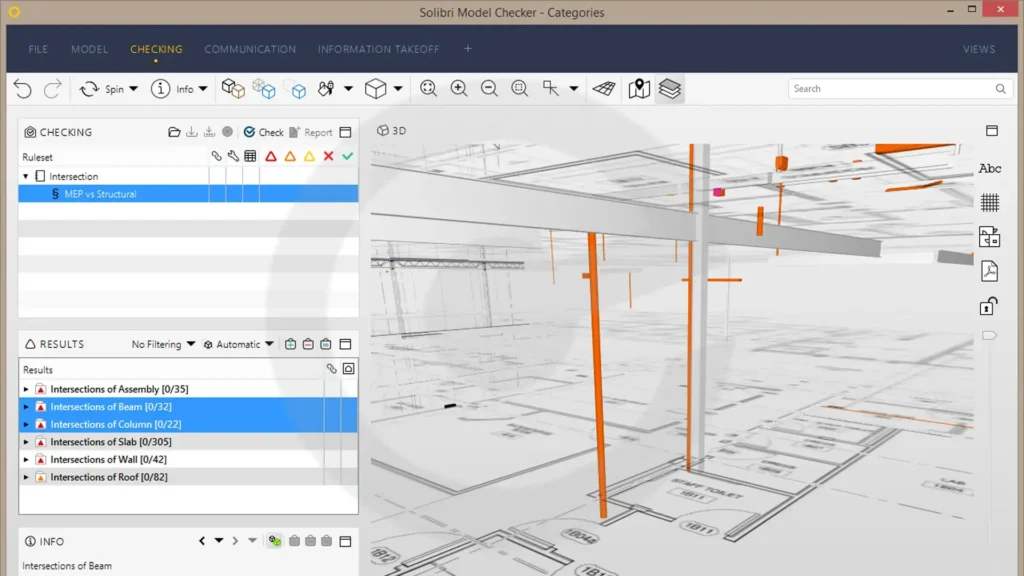

Vendors who model but don’t coordinate. Without active use of BIM clash detection software like Autodesk Navisworks, Revitzo, or BIM 360 Model Coordination, you’re missing the #1 tool that prevents rework.

Teams that implement 3D clash detection early reduce field coordination issues by a significant amount. That means fewer RFIs, fewer change orders, and more predictable schedules.

Signs your vendor lacks clash coordination strength:

- They deliver models but don’t provide clash reports or screenshots

- They aren’t using BIM coordination tools or tracking issues in real-time

- Their models fail basic Revit clash management checks for penetrations, clearances, or sleeve locations

- There’s no audit trail of resolved vs. unresolved issues

What to do:

Make clash detection a non-negotiable in your outsourcing scope. Ask your vendor:

- What software do you use for clash detection? (Autodesk Navisworks? Revitzo?)

- Do you provide federated models and clash snapshots?

- How often do you run coordination reviews?

Mistake 4: Over-modeling or under-modeling the scope

One of the most subtle, but damaging, BIM outsourcing mistakes is getting the Level of Detail (LOD) wrong. Too much, and you get bloated files and sluggish performance. Too little, and your model becomes useless for coordination, prefab, or procurement.

This usually happens when contractors don’t clearly define what should be modeled, or when vendors model everything just to be “safe.” This results in excess geometry, irrelevant families, and lagging performance in building information modeling software like Revit.

Over-modeling mechanical systems leads to bloated files and coordination delays, partnering with experienced mechanical coordination services keeps scope tight and models efficient.

What over-modeling looks like:

- Highly detailed manufacturer families with unnecessary metadata

- Fixtures, bolts, and hangers that won’t be visible or used

- Models that slow down in BIM coordination tools like Navisworks or BIM 360 Model Coordination

Under-modeling examples:

Missing sleeves or embed plates

- Unspecified penetrations or clash zones

- Incomplete equipment clearances, leading to on-site issues later

At Eracore, we always anchor scope to p urpose. If you’re using the model for clash detection in BIM, we model to LOD 300–350, ensuring all geometry is coordinated but not excessive. If it’s for prefabrication, we’ll go to LOD 400, with just the right balance of data and geometry.

Pro tip:

Use a scope matrix that ties each element to a use case: coordination, quantity take-off, installation, or fabrication. That keeps both over-modeling and under-modeling in check, and ensures your models are functional, not just pretty.

Mistake 5: Skipping internal quality checks

Just because you’re outsourcing doesn’t mean you can skip reviewing the work. One of the most overlooked BIM outsourcing mistakes is assuming the vendor’s deliverables are plug-and-play. They’re not.

Even the best external teams need oversight, especially when your name is on the final drawings. Without internal quality checks, you’re risking:

- Misaligned elements that pass visual review but fail in the field

- Non-compliance with your project standards or construction tolerances

- Missed issues in clash detection in BIM platforms due to filtering or overlooked disciplines

Where things often go wrong:

- No redline or markup reviews before sign-off

- Assumptions that clash-free = issue-free

- No verification of Revit family standards, naming conventions, or submittal requirements

- Ignoring “invisible” clashes, like code compliance, workflow conflicts, or clearance zones

We recommend a 3-layer review system:

- Vendor self-checks using tools like Autodesk Navisworks clash detection

- Internal model audits for scope alignment and constructability

- Cross-trade reviews using BIM 360 Model Coordination or Revitzo

This way, you catch both geometry and logic errors before they reach the field.

Mistake 6: Not training your internal team for effective collaboration

You can hire the best BIM outsourcing partner in the world, but if your in-house team isn’t trained to collaborate effectively, the project will still suffer. One of the most underestimated BIM outsourcing mistakes is failing to prepare your internal stakeholders to review, mark up, and coordinate using the same tools and standards as your external team.

Too often, we see internal project engineers or superintendents who:

- Can’t open or navigate federated models in Autodesk Navisworks

- Don’t understand issue tracking systems in BIM 360 Model Coordination

- Struggle to participate in coordination reviews using platforms like Revitzo

The result?

Slower responses, missed issues, and rework that could’ve been prevented.

What good collaboration looks like:

- In-house staff can comment on models, flag clashes, and provide redlines using shared tools

- Everyone understands the clash status dashboard, coordination logs, and naming conventions

- Revit users internally are aligned with your outsourced team on Revit clash management workflows

According to Autodesk, teams using shared coordination platforms like BIM 360 reduce review cycles by up to 30%. But that only works if everyone on your side is trained and actively participating.

Mistake 7: Treating BIM outsourcing as a one-time transaction

One of the most short-sighted BIM outsourcing mistakes is viewing your vendor as a temporary solution rather than a strategic extension of your team.

When you treat BIM like a one-off task, you miss out on:

- Process continuity across project phases

- Long-term efficiency gains from vendor familiarity

- Strategic input on constructability, prefabrication, and field coordination

Most projects evolve. Models need updates, change orders happen, and as-built deliverables become part of your closeout package. Teams that view outsourcing as transactional often find themselves scrambling to re-engage vendors, or worse, re-explaining everything from scratch.

Pro tip:

Treat your BIM vendor like a trade partner. Loop them in early, share lessons learned, and keep them aligned across scopes. That’s where the compounding value of outsourcing really kicks in.

Avoid the common pitfalls, maximize the real value of BIM outsourcing

BIM outsourcing has the power to accelerate timelines, reduce field errors, and free up your internal team, but only if it’s done right. From skipping the BIM Execution Plan to ignoring clash detection in BIM, these mistakes are expensive.

With the right partner and tools, contractors can avoid rework, improve constructability, and deliver smarter projects from day one.

At Eracore, we specialize in helping contractors outsource BIM with confidence. Our process-driven approach, hands-on coordination support, and deep expertise in building information modeling software ensures every model is not just “clash-free,” but field-ready and buildable.

FAQs

What should you look for when hiring a BIM service provider?

Look for a team with good experience and strong skills. Check if they know the latest software and codes. Make sure they can finish work on time and talk clearly with your team.

Why is clash detection so important in outsourced modeling projects?

Clash detection finds places where parts of the building bump into each other. It helps stop problems before people start building. This saves time and money and keeps projects running smoothly.

How much detail should be included in outsourced models?

Models should have enough detail to build from and avoid mistakes. They should show sizes, places for parts, and important notes. The right amount of detail depends on how the model will be used.

What quality checks are needed when reviewing outsourced BIM work?

Check if the model follows the rules and project standards. Look for missing parts or wrong sizes. Make sure there are no clashes and that the model matches drawings and plans.

How can in-house teams collaborate effectively with outsourced BIM teams?

They should talk often and share updates. Use the same software and rules. Keep models up to date so everyone works with the same information. Good communication helps avoid mistakes.

Pro tip:

Don’t overcomplicate it. A simple scope document with clear milestones, software versions, and clash detection software protocols can save weeks of back-and-forth and lay the groundwork for a more effective, collaborative partnership.